Continuous power quality monitoring with the Sonel PQM-750 stationary analyser

The PQM-750 analyser is Sonel’s answer to the growing demands of the power market. Developed for precise, continuous monitoring of network parameters, it is distinguished by its compact design, modular structure and advanced functionality.

Evolution of power quality analysers

Sonel has been developing its range of power quality analysers for many years. Starting with the pioneering Sonel PQM-701, through the next generations of Sonel PQM-700 / PQM-707 meters, and ending with the advanced Sonel PQM-711 Class A model. All of these instruments were portable and well suited for measurements and diagnostics at various measurement points – wherever there was a problem to be solved.

However, over the years – with the development of technology, the transformation of the power industry and the change in the pattern of electricity consumption – the need for continuous monitoring of network parameters has emerged, simultaneously at multiple points in the power system. Variability of loads, distributed generation, supraharmonic, uncontrolled power dissipation, asymmetrical loads and many other phenomena, cause serious threats to stable system operation. So parameter monitoring, data aggregation and alerting at critical moments are crucial today. The Sonel PQM-750 stationary power quality analyser was developed for such tasks.

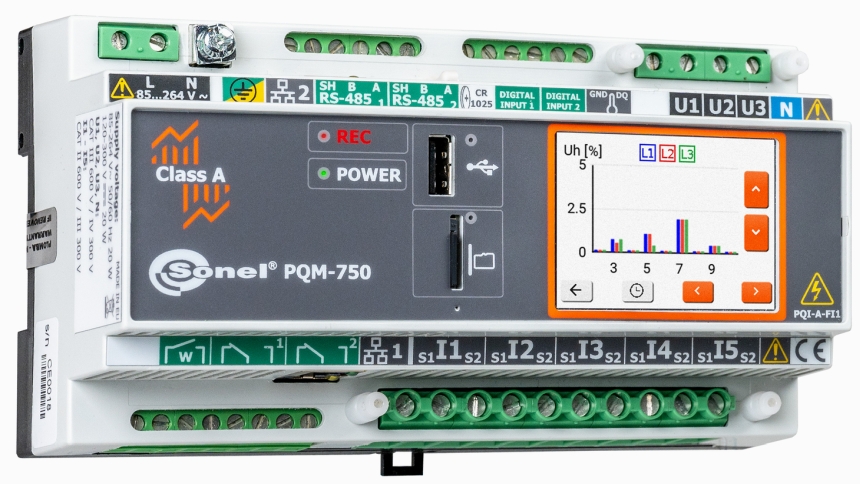

Image 1. Sonel PQM-750 analyser

Class A precision – the highest measurement standards

Analysers can be divided according to various criteria, but one of the most relevant is the class of analyser. The IEC 61000-4-30 standard distinguishes between two classes: A (from Advanced) and S (from Survey). Class S meters have weaker performance and their measurements may give larger differences at the same measuring point for equipment from different manufacturers. Class A meters, on the other hand, are uncompromised and, connected at the same point, should indicate the same results. The Sonel PQM-750 is a certified Class A analyser. This is confirmed by a document from an accredited testing laboratory. In this way, you can be sure that multiple units of this device at different points in the network will measure its parameters with due precision. Regardless of class A, the analyser is built on high-quality components. A 24-bit analogue-to-digital converter takes care of the data processing quality. The sampling frequency of the signals can reach 80 kHz. Harmonic measurements of up to 256, frequency band monitoring up to 150 kHz for super-harmonics, active energy measurement in the 0.2S class – these are just some of the analyser’s strengths. The fact that it can record more than 15,000 parameters at any one time is testament to its sophistication.

Compact design and easy installation

It is not only precise measurements that are constitute an advantage of the analyser. The unit has a small enclosure, which is extremely important for installation in switch cabinets. Often there is not much room for expansion and adding a larger device is not possible. The compact Sonel PQM-750 enclosure, suitable for mounting on a DIN-TH35 rail, does not take up much space, allowing the analyser to be installed without problems in areas where there is already a working infrastructure. However, should the need arise, a wall-mounting kit is provided with the analyser.

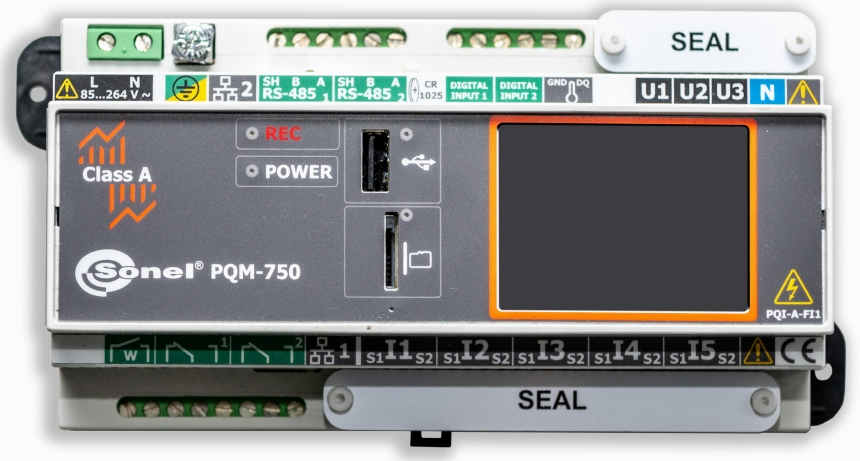

Photograph 2. Mounting the Sonel PQM-750 analyser on a DIN-TH35 rail

In such a small enclosure, however, there is no lack of functionality that is important for energy suppliers, namely the ability to seal voltage and current inputs. In this way, any interference with the connection system can be clearly diagnosed.

Photograph 3. Sonel PQM-750 analyser with current and voltage input protection

Adaptable to different requirements thanks to modularity

In the case of the Sonel PQM-750, it is impossible not to mention its modular design. As standard, the analyser is offered as a main unit, which contains the necessary components for operation:

- 5 inputs for measuring voltages up to 1000 V;

- 5 built-in current transformers with a rated range of 5 A;

- 2 digital inputs and a 1-wire temperature measurement interface;

- 2 controllable relay outputs;

- a relay with a watchdog function;

- built-in power supply with a voltage range of 85…264 V AC / 120…300 V DC;

- built-in Li-Ion rechargeable battery to power the meter in the event of a power failure on the main power supply or PoE supply;

- Li-Ion battery to support the internal clock;

- 2 built-in Ethernet ports for communication with servers; one of the ports allows the meter to be powered from the LAN in the PoE standard; synchronisation with an NTP time server is possible via the LAN port;

- two built-in RS-485 ports, one for communication and the other as a receiver of IRIG-B signals for precise time synchronisation of the analyser;

- built-in USB host port for analyser operation;

- built-in memory and a microSD card slot for data storage;

- a 2.4″ colour touchscreen for basic on-site operation of the analyser;

- built-in protocols for data exchange: IEC 61850, Modbus RTU, Modbus TCP/IP, proprietary SonelFrame.

Image 4. Sonel PQM-750 – built-in screen for on-site operation of the analyser

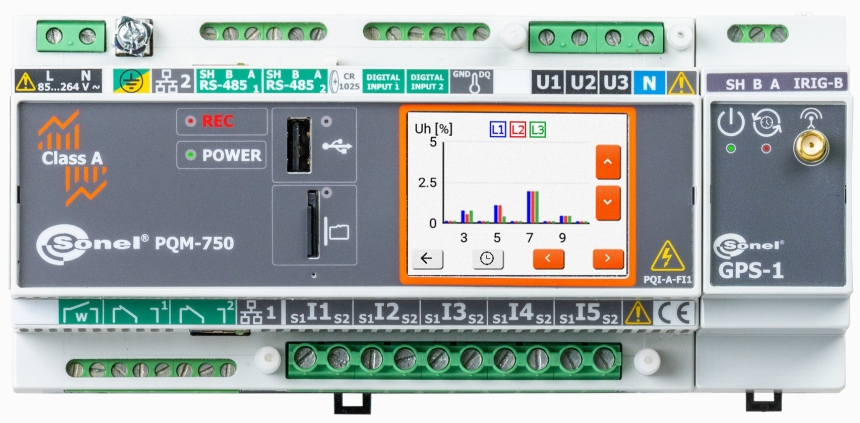

PQM-750 expansion capabilities and optional extensions

The modular design allows the analyser to be adapted to different requirements. The analyser is equipped with an edge connector located on the right side, which is used to connect external expansion modules. From the available extensions, you can choose:

- optional power supply for voltage range 18…60 V DC,

- optional built-in current transformers with a rated range of 1 A,

- internal module for measuring voltage transients up to 6 kV with a sampling frequency of up to 10 MHz.

The manufacturer expects to add further options in the near future, such as:

- optional current inputs for the connection of external current transformers,

- solid-state relays (SSRs) instead of mechanical relays,

- external GPS module for super-precise time synchronisation,

- external GSM module for communication,

- external I/O module,

- external operator panel for full on-site operation of the analyser,

- additional communication protocols.

Image 5. Sonel PQM-750 analyser with external GPS module

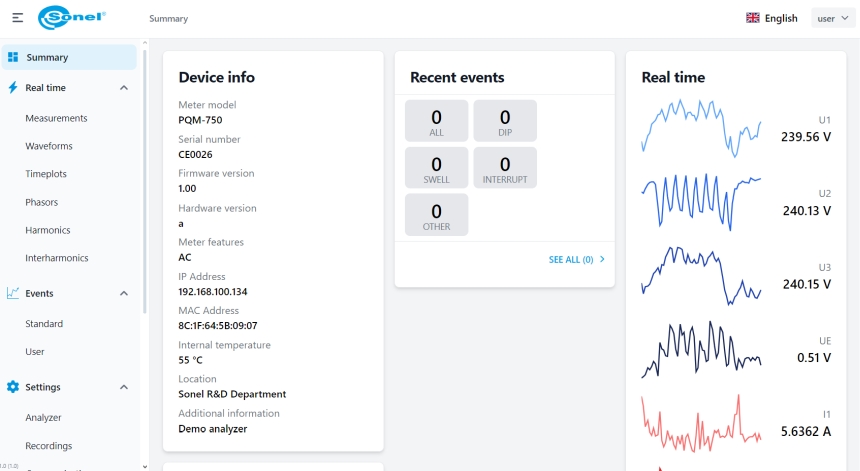

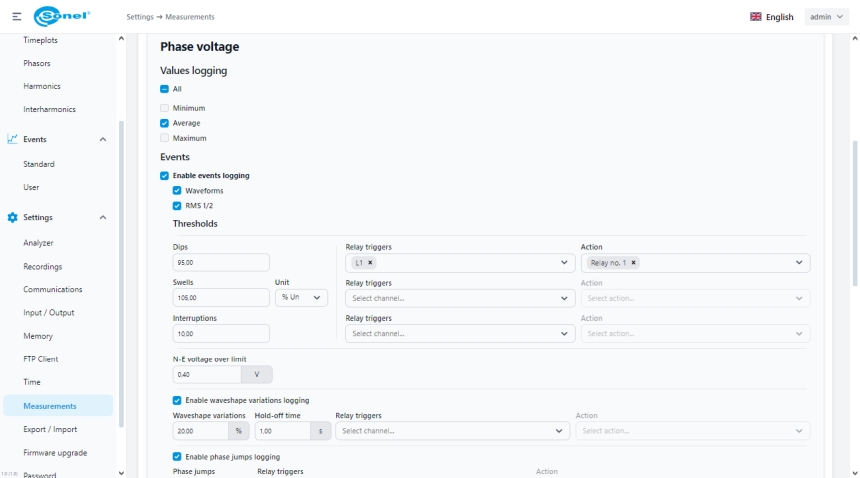

Webserver – convenient operation and remote configuration

The functional complement of the analyser is the built-in web server (webserver). It allows remote configuration, reading of current data or viewing of recorded events from any web browser. Operation is simple and intuitive. The server functionalities are not permanently built in and updates to the meter are planned to expand its capabilities. The ability to both locally and remotely update the analyser is another key value. This makes it quick and easy to update the meter without leaving the office. This is crucial as, with changing market needs, the unit is poised to keep up with these needs and standards.

It is worth noting that the interface on the meter and web server can be operated in several languages. The number of language versions will be increased in the future in line with customer needs, thanks to the possibility of upgrades.

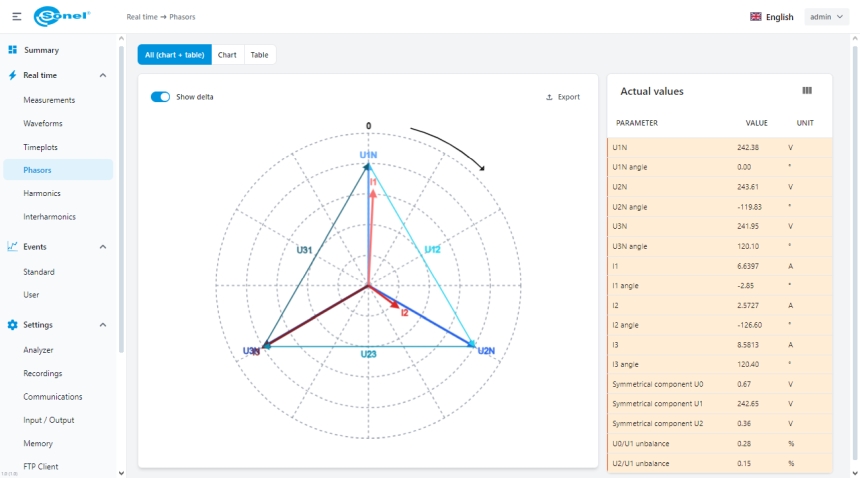

Figure 1. Webserver in Sonel PQM-750 – analyser summary screen

Figure 2. Webserver – indicative diagram

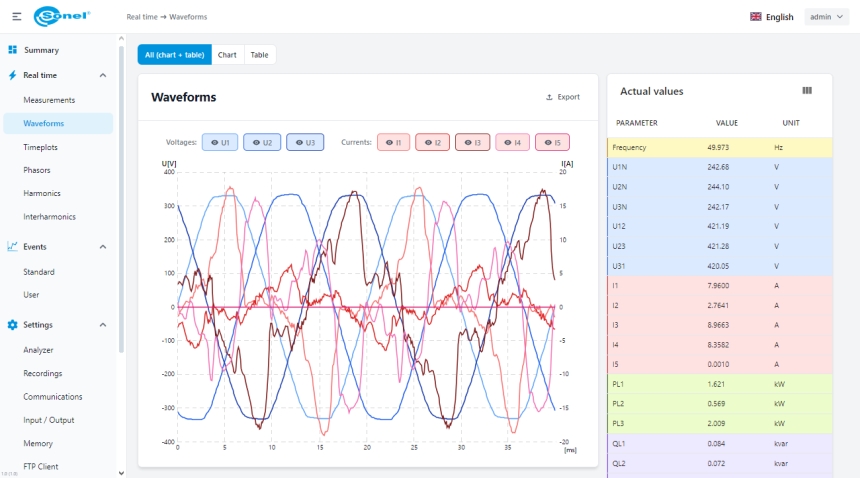

Figure 3. Webserver – example screens of current readings

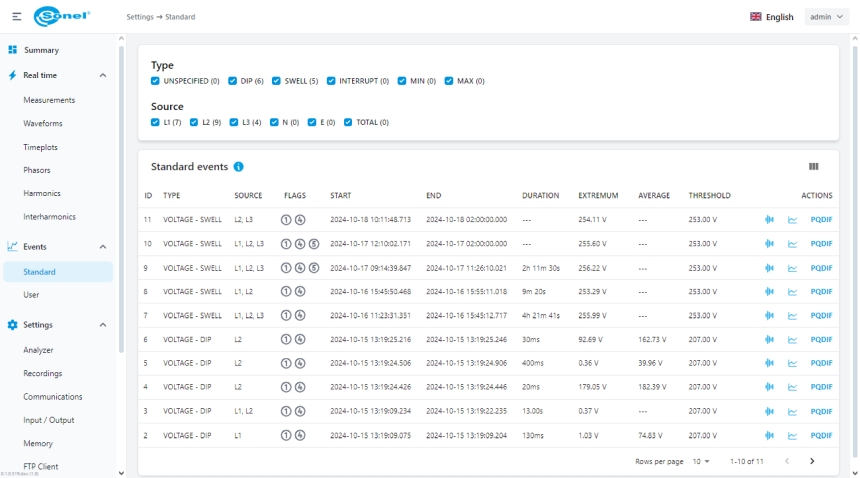

Figure 4. Webserver – information screen of recorded events

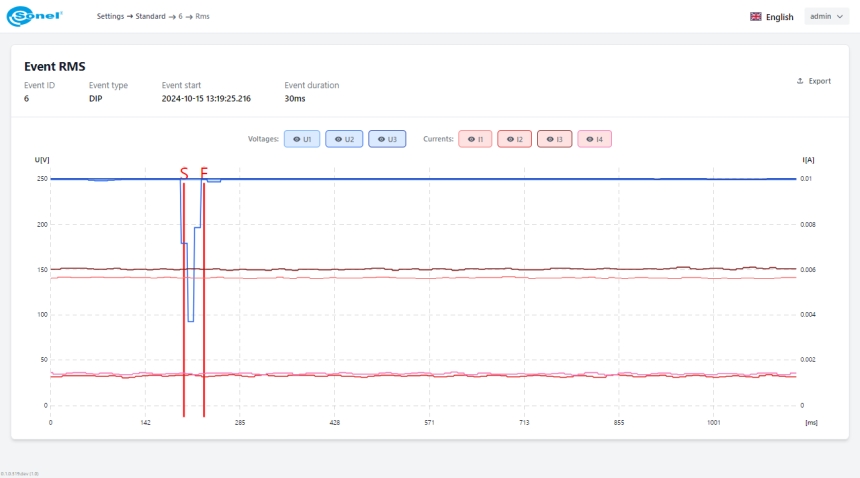

Figure 5. Webserver – graphs of an example of recorded voltage collapse

The built-in server allows extensive configuration of the analyser, which is very important in order to properly adapt its operation to the actual needs of the user. Indeed, it should be borne in mind that an inadequate configuration may result in too much data or reduced security of service.

Figure 6. Webserver – example configuration screen

From the web server, settings can also be made to integrate the meter with the user’s IT systems (e.g. SCADA system). Standard IEC 61850 or Modbus protocols can be used for this purpose. Full integration using SonelFrame proprietary protocol is also possible once a suitable driver has been written. Thanks to the built-in FTP client, the accumulated data in the internal memory can be automatically sent once a day to a designated FTP server as PQDIF files. The PQDIF format is one of the most widely used data exchange formats in the world. Interoperability with virtually any software that uses standard communication protocols ensures the analyser’s versatility.

Cyber security – a sign of the times

The Sonel PQM-750 analyser has a number of features designed to make tampering difficult. Built-in firewall, encrypted in-house software, PIN code to operate the embedded screen, login system to operate the embedded webserver, encrypted data transmission from the webserver are examples of security solutions.

24-hour recording and analysis of energy network parameters

All this makes the Sonel PQM-750 analyser a powerful tool for 24/7 recording and analysis of power network parameters. Its reduced dimensions, modular design, precise measurements, advanced technology, ability to interface with database and SCADA systems are undoubted advantages that provide the power sector (generation and distribution), industry and service companies with a high-end power quality monitoring meter.

Author: mgr inż. Marcin Szkudniewski, Sonel S.A.

No Comment