How to perform measurements of emergency lighting?

The article presents the requirements contained in legal acts and standards for emergency lighting. It also touches on the aspects of performing measurements of emergency lighting intensity and the most common problems faced by the measurement team.

Introduction

Nowadays, we can not imagine life without electric lighting. Light plays a huge role in our lives. It allows you to “extend the day”, with positive and negative effects. We are so accustomed to artificial lighting that we do not realize what the risks of its lack are. Due to the unreliability of electric lighting – usually resulting from the power supply decay, it was necessary to create a system protecting against the effects of its lack. To prevent unexpected fading of light, and thus to avoid the panic effect in public facilities, where a large number of people can be used emergency lighting. Emergency lighting is an additional source of energy, supplying selected luminaires with basic lighting or luminaires specially designed for this purpose.

The scope of application

Emergency lighting installations should be designed in all construction works, where the loss of voltage in the electricity supply network may cause a threat to human life or health, serious environmental hazards, as well as considerable material damage.

The standard for emergency lighting EN 1838 informs that the time of operation of the evacuation lighting should be adapted to the conditions existing in the construction work, but it can not be shorter than 1 hour from the moment of switching on. In the EN 1838 standard Lighting application. Emergency lighting. the minimum values that emergency lighting systems should meet are specified. It refers to other standards, eg. EN 50172 Emergency lighting systems specifying emergency lighting installations, or EN 60598-2-22 Lighting fittings. Part 2-22: Specific requirements. Luminaires for emergency lighting.

Emergency lighting should be used:

– In rooms:

- the audience of cinemas, theaters and philharmonics,

- auditoriums, conference rooms, entertainment venues and sports halls designed for over 200 people,

- exhibition in museums,

- with an area of over 1000 m2 in garages lit only with artificial light.

– On escape routes:

- from the rooms mentioned in the above point,

- lit only with artificial light,

- in hospitals and other buildings intended primarily for the stay of people with limited mobility,

- in high and high-rise public buildings and a collective residence.

– In temporary buildings, if they are intended for spectacular or other gatherings of people.

Types and objectives of emergency lighting

Emergency lighting, the general purpose of which is to ensure a safe exit from the place of stay, during the loss of normal power supply, should be supplied from an independent power source. According to EN 1838, emergency lighting includes: emergency escape lighting and spare lighting (Fig.1).

Fig. 1. Types of emergency lighting, according to EN 1838

Emergency escape lighting can be divided into:

1. Illumination of escape routes

Its purpose is to ensure safe leaving the place of stay, as well as to ensure visibility and easy locating and use of fire equipment and safety equipment. Illumination of escape routes should be designed so that the damage of even one light fitting does not cause the road to become dark.

Requirements:

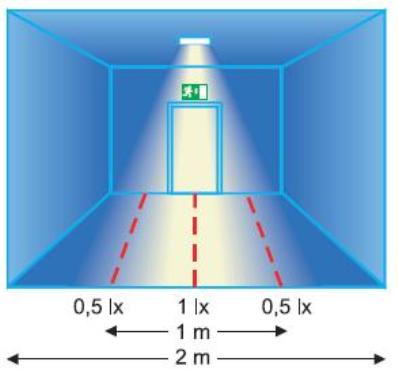

In the case of escape routes up to 2 m wide, the illuminance on the floor in relation to the central line of the evacuation route (axis) should not be less than 1 lx, and on the central lane – no less than half the width of the road – the intensity should be at least 50% of the value given (Figure 2). It is also important to maintain the uniformity of lighting and it is required that the ratio of maximum to the minimum illuminance along the central line of the escape route should not be greater than 40:1.

Ud=Emin/Emax (1)

If the first aid points and fire-fighting devices and alarm buttons are not in the escape route or in the open area, they should be so lit that the illumination on the floor in their vicinity is at least 5 lux. The minimum value of the color rendering index (Ra) of the light sources used should be not less than 40.

Fig. 2. Determination of the center of the road and the center lane

Time:

The minimum duration of use of lighting in the escape route according to EN 1838 for evacuation purposes should be 1 hour, with 50% of the required illuminance to be generated within 5 s and the full level within 60 s.

2. Lighting of the open area (eg. gymnasium, hall, auditorium)

The purpose of lighting the open zone is to reduce the likelihood of panic, to facilitate the identification of evacuation directions and to allow safe movement of people towards escape routes. This lighting is used in zones with unspecified evacuation routes in halls or in facilities with a floor area of more than 60 m2 or smaller, if there is an additional threat caused by the presence of a large number of people.

Requirements:

The value of the open area emergency lighting intensity should not be less than 0.5 lux at the level of the floor used during normal activity, except for the separated 0.5 meter perimeter area, while maintaining a uniformity of not less than 1:40, (1). It is recommended that obstacles occurring at a height of up to 2 m (measured from the floor) are also illuminated. And the minimum value of the color rendering index (Ra) of the light sources used should be not less than 40.

Time:

The minimum duration of lighting for evacuation should be 1 hour, whereas in the open area 50% of the required lighting should be generated within 5 seconds and the full level within 60 seconds.

3. Lighting of the high risk zone (workplace with a special threat)

Its purpose is to increase the safety of people who take part in a potentially dangerous process or are in a potentially dangerous situation, as well as to allow proper completion of actions and moving people towards the escape route. Workplaces with a particular threat could include works, works at heights, as well as work with hazardous materials.

Requirements:

In high-risk zones, the back-lighting intensity on the reference plane should not be less than 10% of the operational illuminance required for the operations concerned, however, it should not be less than 15 lux. The stroboscopic effect must be eliminated. The uniformity of illuminance in a high risk zone should not be greater than 10:1.

Ud=Emin/Emedium (2)

When designing such lighting, the maintenance system should be taken into account, because a lighting intensity is required, eg. below which the light intensity is not allowed to drop.

Time:

The minimum working time of high-risk zone lighting is the time when there is a risk to people in a given process. It is determined individually by the employer. This lighting should provide 100% of the required illuminance after 0.5 seconds from commissioning.

Spare lighting

Spare lighting, or part of emergency lighting, enabling the continuation of normal activities. It can be used as an escape lighting, but must meet all requirements as for emergency lighting in accordance with EN 1838. If the illumination is less than the minimum level under basic lighting, then the lighting can be used only to complete the task or to interrupt the work.

The basic definitions related to emergency lighting include:

- Emergency exit: output intended for use during a breakdown.

-

Safety signs: a sign that provides general safety information, obtained by a combination of color and shape, and detailed safety information by adding a graphic symbol or text. There are signs:

- Safety sign illuminated externally: illuminated sign, (if required) by an external light source (fig. 3).

- Internally illuminated safety sign: illuminated sign (if required) by the internal light source (fig. 4).

Fig. 3. Safety sign illuminated externally

Fig. 4. Safety sign illuminated internally

Requirements:

The luminance of each part of the colored mark shall be at least 2 cd/m2 in all security orientations. The ratio of the maximum to the minimum luminance of both white and colored parts of the safety signs should not be greater than 10:1. However, the ratio of the luminance of the white part of the mark to the luminance of the colored part of the mark should not be less than 5:1 and larger than 15:1.

Time:

The signs shall be illuminated in such a way that they reach luminance of 50% of the required luminance within 5 s and reach luminance within 60 s of the required value.

The maximum distance of view of illuminated signs should be determined from the equation:

l=z•h (3)

where:

l – distance of observation,

z – is a variable depending on the lighting method of the sign and accepts values:

100 – for externally illuminated signs,

200 – for internally illuminated signs,

h – height of the sign.

It is recommended that the safety mark, due to good visibility, be mounted no higher than 200 above eye level.

Fig. 5. Observation distances – diagram

Performing tests

Measurements of evacuation lighting are made in places marked as an escape route. According to the EN 1838 standard, the evacuation route should be illuminated with its intensity of min. 1 lx. When selecting measurement points, it is recommended to take distances between them from approx. 1 m to 2 m. And also the principle that the more measuring points the more reliable the measurement result will be. For roads up to 2 m wide, illuminance should be tested on the floor along the middle of the road and in the central lane, which is at least half the width of the road. However, when the evacuation routes are wider than 2 m, they can be divided into several roads with a width of 2 m, route the evacuation route with the center, and the area not covered by the open zone or treat the entire space as an open zone.

In high-risk areas, the operating light intensity is examined on a selected surface designated as a hazardous zone. In addition, in high-risk zones, the emergency lighting time should be checked. Its full required lighting should be provided within 0.5 s.

The measurements of the emergency lighting intensity are carried out on the reference (work) plane, – at the height of the floor or stairs.

| Place of installation of lighting devices | Required level of illuminance at floor level* | Emax/Emin | Comments: |

| Middle line of the escape route with a width of up to 2 m |

1 lx | 40:1 | time of attachment 5 s→ 50%E 60 s→100%E |

| The sides of the escape route up to 2 m wide | 50% E the middle line of the escape route (min. 0,5 lx) |

40:1 | – |

| Open area | 1 lx | 40:1 | time of attachment 5 s→ 50%E 60 s→100%E |

| High risk zone | Min. 10% En≥15 lx | 10:1 | time of attachment 0,5s→100%E |

| First aid points, fire devices and emergency buttons outside the evacuation route or the open area | 5 lx | – | time of attachment 5 s→ 50%E 60 s→100%E |

* due to the necessity of recognizing colors, the minimum value of the color rendering index Ra of the applied light sources can not be lower than 40, and the luminaires can not affect the change of this value

Measurements of emergency lighting should be carried out in the appropriate class of luxmeter, because we are dealing with very low values of illuminance. Therefore, the meter used must be able to measure such values. Similarly, in high-risk zones, where it is necessary to check the uniformity of light intensity with very high resolution. In addition, the luxmeter should have a valid calibration certificate that confirms the device’s efficiency and its declared levels of spectral and basic uncertainty, because the photoelectric cell being a sensor is aging, so it should be subjected to periodic metrological control. The meter should have an error tolerance not exceeding 10%. Sonel LXP-10B and Sonel LXP-10A models are recommended here.

Post-completion documentation

There are no regulations regulating the forms of as-built documentation from lighting measurements. However, a minimum should be kept in terms of content that will allow for unambiguous evaluation of the tests performed. The measurement contractor can use ready-made templates or use computer programs to perform the test report. One of the recommended programs is the Foton program, developed by DASL Systems in cooperation with SONEL S.A. The program is designed for people performing lighting intensity tests, allowing for the implementation of measurement protocols.

Summary

Emergency lighting ensures safe use of buildings and other facilities. It belongs to fire-fighting equipment. Since the installation of emergency lighting is part of the emergency lighting installation, all fire-fighting equipment should be inspected and meet the requirements of the standards.

Emergency emergency lighting is very important especially in rooms used by a large number of people, such as cinema halls or theater halls, where with the basic lighting turned off, additional lighting should be installed, powered with an acceptable long-term safe voltage. Its aim is to show architectural obstacles, such as stairs, high thresholds. Thus, emergency lighting is intended to prevent panic and safe evacuation of rooms or endangered zones.

Appendix

European Directives

There are two European directives that govern the need for Emergency lighting

- The construction products directive (89/106/EEC) “to ensure that lighting is provided promptly, automatically and for a suitable time when normal power supply to the lighting fails”

- The workplace directive (89/654/EEC) “specific emergency routes and exits must be indicated by signs” “emergency routes and exits must be provided with emergency lighting of adequate intensity in case the lighting fails”

Country-specific requirements for emergency lighting (deviations from EN 1838)

France

Products for emergency lighting must be certified and have defined quality features. Luminance and illuminance levels are not taken into consideration in planning.

Safety lighting for escape routes:

- Certified emergency luminaires

- Maximum distance between the luminaires 15 m (30 m in schools)

- Positioned at each door used as an emergency exit

- near stairways for directly illuminating each stair

- near every change in level

- at every change of direction

- at every junction in passageways and corridors

Anti-panic lighting:

- Certified emergency luminaires must provide 5 lm/m² of floor area

- At least two luminaires per room

- Distance between the luminaires less than four times the installed height (distance from floor to luminaire)

Safety lighting for hazardous workplaces:

- EN 1838 does not correspond to French regulations

- The basis is a risk assessment

Safety signs:

- French standard NF 08-003

- or compatible standards of other European countries. In public buildings and workplaces, illuminance is not used as a photometric parameter.

Italy

Public places such as cinemas and theatres:

- An illuminance of at least 5 lx near stairways and exits (measured 1 m above floor level)

- At least 2 lx along escape routes

Illuminance values are not to be taken as planning values if they are based on specifications. They must be capable of being measured on site including reflections.

Germany

Safety lighting for escape routes and anti-panic lighting in workplaces:

- Maximum time of 15 seconds between failure of the general lighting system and achievement of the necessary illuminance levels (Workplace Directive § 7 Section. 4, Workplace Guidelines ASR 7/4

United Kingdom

The following requirements apply to start-up of the emergency lighting system:

- Within 5 seconds of failure of the general lighting system

- In buildings that are used mainly by people who know the escape routes: the authorities are at liberty to extend this period to a maximum of 15 seconds (1988 “Emergency Lighting”, BS 5266 Part 1)

Horizontal illumination of escape routes (which are unobstructed):

- at least 0.2 lx along the central axis

- at least 0.1 lx over half the width (for widths up to 2 m)

- wider escape routes: division into 2 m wide zones, illumination as above (1988 “Emergency Lighting”, BS 5266 Part 1)

Ireland

The following requirements apply to start-up of the emergency lighting system:

- within 5 seconds after failure (1989 “Code of Practice for Emergency Lighting”, I.S. 3217)

Horizontal illumination of a clearly identified escape route:

- at least 0.5 lx along the central axis at floor level (1989 “Code of Practice for Emergency Lighting”, I.S. 3217)

Authors: Dorota Kołakowska, Adam Szczepanik – Sonel S.A.

Products mentioned in the article:

No Comment