Comprehensive diagnostic testing of electric vehicle charging stations using the Sonel EVSE-100 multifunction analyser

The dynamic growth of electromobility calls for modern diagnostic tools that can ensure the safety and reliability of electric vehicle charging stations. One such solution is the Sonel EVSE-100 – a multifunction analyser specifically designed to comprehensively test EV charging infrastructure.

The Sonel EVSE-100 enables the verification of an EV charging systems functionality and protective measures, as well as being able to detect possible faults in charging circuits. Thanks to its broad range of CP and PP circuit simulation, advanced diagnostic functions and portable design, the Sonel EVSE-100 helps make the everyday work of E-mobility professionals easier and more efficient. Instead of using several meters, users are equipped with one versatile instrument capable of performing a full range of tests and can generate professional measurement reports from the results.

Figure 1. Testing of EV charging stations using the Sonel EVSE-100

Versatile applications of the Sonel EVSE-100 in EV charging station diagnostics

The Sonel EVSE-100 offers extensive testing capabilities in the field of electromobility, which support the comprehensive diagnostics of various test objects:

- Diagnostics and testing of stationary EV charging stations (AC EVCS). The EVSE-100 allows for the full testing of Mode 3 EV charging stations equipped with either a socket or a permanently connected charging cable, in accordance with IEC 61851-1 and IEC 60364-6 standards. These may include single-phase or three-phase wallboxes or pole-mounted chargers installed outdoors.

- Diagnostics and testing of portable EV charging stations (ICCB). The analyser enables activation and testing of single-phase and three-phase Mode 2 portable chargers. It supports safety measurements and fault simulation on both the supply and vehicle side.

- Testing of EV charging cables. The EVSE-100 allows for basic safety testing of Mode 3 charging cables without the need for additional test equipment.

- Low-voltage electrical installation safety testing. During diagnostics, it is often necessary to assess the supply installation (e.g. switchboard) feeding the EV charging station. By using standard leads and crocodile clips or needle probes with the AEV-100 adapter (included as standard), the EVSE-100 can also be used as an electrical installation safety tester for these tests.

Figure 2. Testing of EV charging stations using the Sonel EVSE-100

Advanced measurement and diagnostic capabilities of the Sonel EVSE-100

The Sonel EVSE-100 is a high-end analyser supporting electrical safety measurements, diagnostic analysis, and simulation of operating and fault conditions. The meter offers a wide range of testing functions:

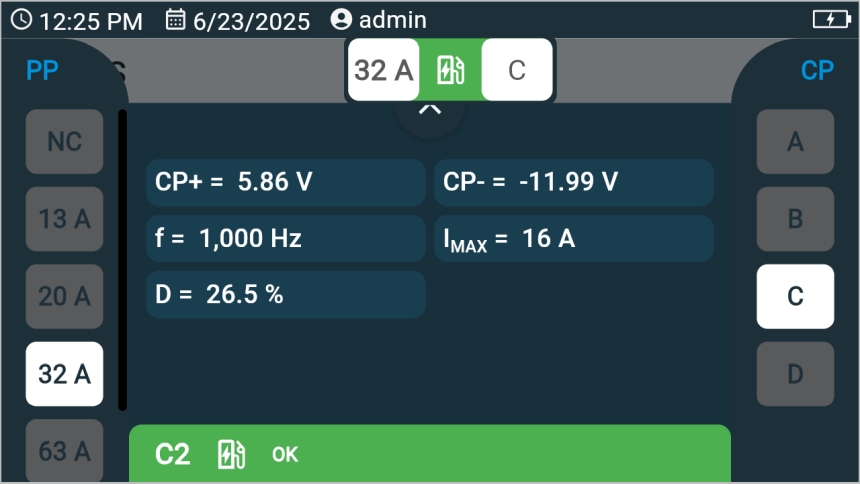

Simulation of PP cable parameters:

- open circuit,

- 13 A, 20 A, 32 A, 63 A, 80 A.

Simulation of CP communication:

- state A – vehicle not connected,

- state B – vehicle connected, not charging,

- state C – vehicle connected, charging without ventilation,

- state D – vehicle connected, charging with ventilation.

Safety measurements:

- measurement of the short circuit loop Z,

- measurement of the parameters of RCD circuit breakers (AC, A, B, 6 mA DC)

- measurement of the insulation resistance RISO,

- measurement of RCONT,

- phase sequence indication,

- measurement of the resistance of coding resistor RC,

- measurements of the grounding RE.

Figure 3. Fault loop impedance measurement at an EV charging station using the Sonel EVSE-100

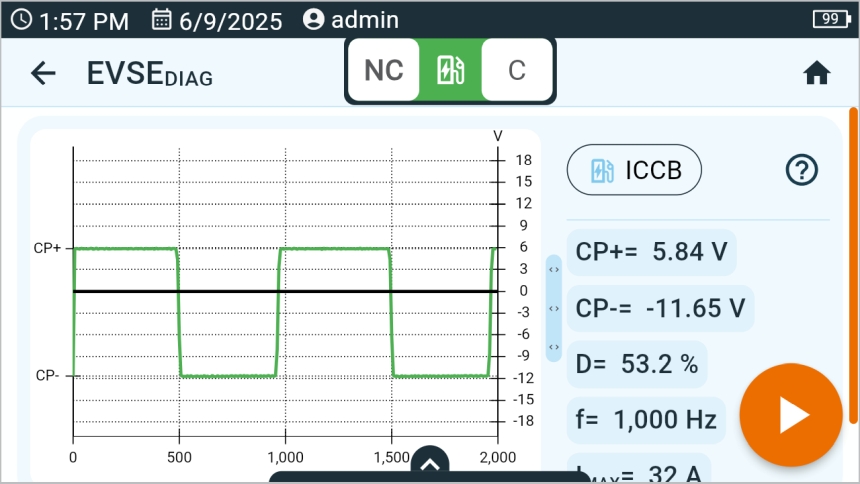

EVSE analysis – diagnostics:

- CP+, CP- voltage,

- frequency f (PWM),

- signal filling D (PWM),

- maximum charging current IMAX,

- graph of CP+, CP-, f, D, IMAX,

- toff off time,

- ton on time.

Figure 4. EVSE-100 – CP signal diagnostic screens with waveform display

EVSE analysis – simulation of errors (ICCB, EVCS):

- CPsh – short circuit of CP to PE,

- Dsh – diode short circuit,

- PEop – interruption in PE.

Simulation of power supply circuit faults (ICCB):

- L1op – interruption in phase L1,

- L2op – interruption in phase L2,

- L3op – interruption in phase L3,

- Nop – interruption in N,

- PEop – interruption in PE,

- L↔PE – interchanged L and PE wires

- UEXT(PE) – voltage on PE wire.

EVSE analysis:

- transition time between states.

Comprehensive standard test kit and optional accessories

The standard test kit of accessories supplied with the Sonel EVSE-100 is complete with everything needed to fully utilise the meters capabilities. The kit includes a separate pouch for test leads, crocodile clips and probes, as well as the AEV-100 adapter for low-voltage installation testing.

A 2.2m Type 2 cable is also included for connecting to socket-equipped EVSEs (i.e. stations without a permanently attached cable). The set is complemented by a USB cable for PC communication and a BNC adapter for oscilloscope integration.

Additional optional accessories are available to further extend the measurement capabilities of the device. The complete list of accessories can be found on the Sonel website.

Figure 5. Sonel EVSE-100 – standard accessories included

Integration with Sonel MeasureEffect™ – smart measurement management

The Sonel EVSE-100 is fully integrated with the MeasureEffect™ platform. Measurement data can be automatically synchronised with the cloud and assigned to predefined objects. Through the web application, users can create custom measurement procedures—tailored to specific objects, standards, or individual requirements—and manage the database. The database can include parameters such as circuit breaker types, installation configurations, manufacturers, and other essential settings. As a result, each subsequent measurement is carried out faster, more accurately, and without the need to manually configure the device on-site.

A fully synchronised working environment allows other team members to monitor the measurement progress in real time. The technician in the field can immediately upload data to the cloud, the supervising engineer can view the current task status and the person responsible for reporting can instantly generate a complete set of documentation. This workflow significantly shortens project delivery time, improves operational transparency and enhances team efficiency.

Thanks to a wide range of communication interfaces (USB, LAN, Bluetooth and Wi-Fi), the Sonel EVSE-100 can also operate with additional accessories. Label printers or QR code scanners can help automate the process of performing periodic measurements. Once a QR code is scanned, the analyser can identify the object, recall the previously used procedure and automatically initiate the appropriate test sequence. After completing the measurement, the results are assigned to the correct location within the test objects structure. This greatly reduces operator workload and increases the consistency, repeatability and safety of the diagnostic process.

A new standard in EV charging station diagnostics

The introduction of the EVSE-100 analyser to the Sonel product portfolio marks a major breakthrough in the field of electric vehicle charging station service and diagnostics. With comprehensive measurement capabilities and intuitive operation, along with its integration with the MeasureEffect™ platform, this device is a powerful tool for electromobility professionals.

The Sonel EVSE-100 is an investment in modern diagnostics and safety, successfully combining high measurement efficiency with everyday ease of use. The analyser not only streamlines diagnostic workflows but also helps raise the reliability standards of the entire EV charging infrastructure – from cables and portable stations to fixed charging points.

Author:

Tomasz Gorzelańczyk, Sonel S.A.

No Comment